Pompeii had streets repaired with iron before it was buried, according to recent research

11/08/2019 / By Edsel Cook

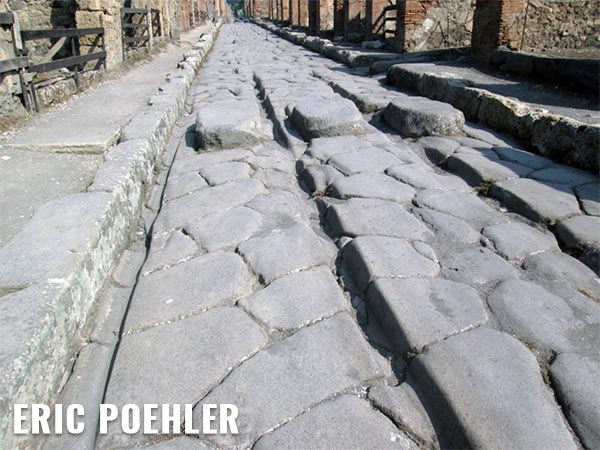

Like any ancient Roman city, paved stone covered many of the streets of Pompeii. However, it recently came to light that workers – who were possibly slaves – repaired damaged parts by pouring molten iron into the ruts.

Once the iron cooled, it filled up the ruts carved into the paved stone street by the constant passage of wheeled carts. The technique appeared to be faster than repaving the entire stretch of the road.

A newly published study delivered the details on this ancient and novel approach to street repair. The researchers called it the first large-scale evidence that the ancient Romans made and employed molten iron in such a way.

In A.D. 79, Mount Vesuvius erupted with unprecedented force. It unleashed tremendous amounts of ash and lava upon the nearby city of Pompeii, located near modern-day Naples, Italy.

The volcanic eruption killed most of the people of Pompeii who failed to flee in time. However, the natural disaster also preserved the buried city and its mummified inhabitants.

Excavations in Pompeii provided plenty of evidence about life in ancient Rome. But modern-day researchers never imagined that the Romans repaired stone streets with molten iron. (Related: Ancient Romans created super strong concrete by mixing aggregate with mineral-rich sea water.)

Ancient Romans used molten iron to repair holes in their paved stone streets

Many of the streets of Pompeii featured stone pavements. However, a 2014 survey revealed that even the durable material eroded over time as wheeled carts rolled over them time and time again.

Eventually, the surface of the stone pavements developed deep ruts. The damage made travel slower, harder, and rougher for everyone.

It took many months and considerable resources to repave a stone street. Worse, the repair job would close down the route to traffic.

Everyone would have to use alternative paths that took more time. To compound matters, some of Pompeii’s heavily used streets eroded quickly.

Researchers from the University of Massachusetts Amherst (UMass Amherst) and the University of Texas at Austin (UT Austin) found that high volumes of traffic on narrow streets might wear down a stone-paved surface within a few decades.

“The Pompeians devised another option [for street repair] that was ingenious and unconventional: after heating iron or iron-rich slag to a molten state, they poured out hundreds of individual repairs onto, into and below the paving stones of the city’s most important streets,” they reported.

Slaves likely performed the dangerous job of carrying and pouring liquefied metal

Pouring molten iron into the holes filled the gaps quickly and thoroughly. Repair workers also inserted ceramics, terracotta, stone, and other materials.

Once the iron cooled down, it became hard enough to withstand traffic. The ancient Romans seemed to prefer this partial repair job over the arduous project of repaving the street.

“How the Romans introduced liquefied iron material into the streets at Pompeii remains a mystery,” the researchers brought up.

The ancient Romans needed to heat the metal or slag to between 2,012 to 2,912 F (1,100 to 1,600 C). Tests with reconstructed furnaces showed that those temperatures were possible.

During their study, the researchers came across many examples of iron droplets on undamaged parts of the streets. They interpreted these drops as accidental spills while transporting the molten metal.

UMass Amherst researcher Eric Poehler theorized that slaves hauled the molten iron through the streets of Pompeii. Roman cities owned public slaves, and the magistrates who effectively ran them also had slaves.

Poehler and his colleagues plan to study the chemical composition of the iron that filled up the holes in Pompeii’s streets. They want to know where the metal came from.

Sources include:

Tagged Under: ancient history, Ancient Rome, history, iron, natural disaster, Pompeii, research, slavery, streets, volcanic eruptions

RECENT NEWS & ARTICLES

COPYRIGHT © 2018 REALHISTORY.NEWS

All content posted on this site is protected under Free Speech. RealHistory.news is not responsible for content written by contributing authors. The information on this site is provided for educational and entertainment purposes only. It is not intended as a substitute for professional advice of any kind. RealHistory.news assumes no responsibility for the use or misuse of this material. All trademarks, registered trademarks and service marks mentioned on this site are the property of their respective owners.